Now Reading: Predictive Maintenance with Vibration Sensors Driving Reliable Industry

-

01

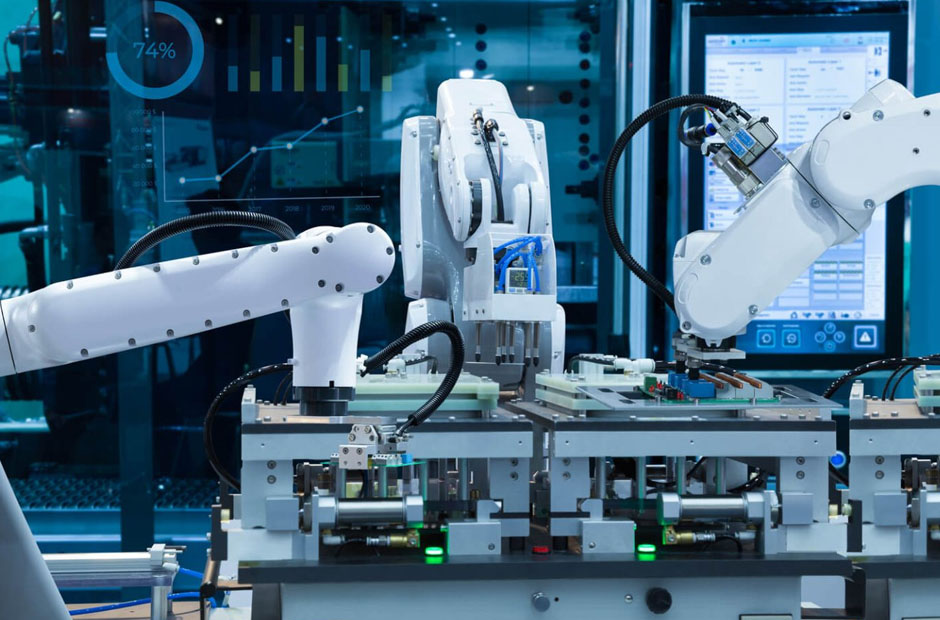

Predictive Maintenance with Vibration Sensors Driving Reliable Industry

Predictive Maintenance with Vibration Sensors Driving Reliable Industry

There’s a particular kind of anxiety that comes with managing critical machinery. You walk past equipment that hums and vibrates, wondering if today will be the day something catastrophic happens. Will that bearing finally give out? Is that subtle change in vibration the warning sign you’ve been trained to catch, or just normal operation? For engineers, facility managers, and maintenance teams worldwide, this uncertainty represents more than just operational risk—it touches something deeper about our relationship with responsibility, foresight, and the systems we’re entrusted to protect.

The vibration sensor has emerged not merely as a piece of monitoring equipment, but as a bridge between reactive panic and proactive confidence. It represents a fundamental shift in how we understand and interact with the machines that power our world, transforming the invisible language of mechanical stress into actionable intelligence that prevents disasters before they unfold. This transformation isn’t just about avoiding downtime—it’s about fundamentally changing how organizations think about maintenance, how teams experience their daily work, and how leaders build cultures of excellence rather than crisis management.

The Hidden Language Machines Speak Through Movement

Every piece of rotating equipment tells a story through its vibrations, though for decades, humans could only listen to these narratives through crude instruments or experienced intuition. Seasoned maintenance technicians would place their hands on machinery, feeling for irregularities, developing an almost mystical sense of when something wasn’t right. This tacit knowledge, built over careers spanning decades, represented an irreplaceable form of expertise—and a vulnerability for organizations when that expertise walked out the door. The challenge wasn’t just technical; it was deeply human, rooted in how we pass knowledge between generations and how we build institutional memory that survives individual departures.

Understanding what a vibration sensor actually does requires stepping back from the technical specifications and recognizing what’s really happening. Machines in motion create patterns—rhythmic signatures that reflect their internal health. A perfectly balanced motor produces one pattern. That same motor with a deteriorating bearing produces something entirely different. The frequencies shift, amplitudes change, and new harmonics appear like discordant notes in what should be a symphony. What makes modern vibration monitoring transformative isn’t just that it detects these changes, but that it democratizes expertise, turning implicit knowledge into explicit data that entire organizations can act upon. It creates a common language where maintenance veterans and new technicians can discuss equipment health with shared understanding and precision.

Why Traditional Monitoring Methods Fall Short of Modern Demands

The evolution beyond periodic inspections and manual checks speaks to a broader cultural shift in how industries approach risk. Walking around with a handheld device once a month creates dangerous gaps—windows where developing problems go unnoticed until they cascade into failures. Consider the psychology of this approach: maintenance teams know they’re playing odds, hoping that nothing critical develops between inspection intervals. This generates stress, breeds reactive cultures, and ultimately costs organizations far more than the equipment itself. Beyond the financial toll, this reactive posture affects how people feel about their work, creating environments where teams constantly brace for the next crisis rather than taking pride in preventing problems before they emerge.

Continuous monitoring through permanently installed sensors fundamentally changes this dynamic. Instead of scheduled glimpses into machine health, teams gain persistent awareness. The transformation mirrors the difference between visiting a doctor when you feel sick versus wearing a device that tracks your vital signs constantly. One approach waits for symptoms to become severe; the other catches subtle deviations before they become crises. For organizations, this shift doesn’t just improve uptime—it changes how people feel about their work, replacing dread with confidence, reactivity with strategy. Maintenance professionals report feeling more empowered, more professional, and more valued when they work with continuous monitoring systems that validate their expertise while extending their capabilities beyond what human senses alone can achieve.

The Psychology of Predictive Maintenance and Human Confidence

When you implement comprehensive vibration monitoring, something interesting happens beyond the technical metrics. Maintenance teams report feeling more in control, more professional, more valued. Engineering decisions become data-driven rather than instinct-driven, which paradoxically doesn’t diminish expertise but elevates it. Experienced technicians find their hunches validated and quantified, their insights now shareable across organizations in concrete terms. This validation matters psychologically—it transforms maintenance from a support function viewed as a cost center into a strategic capability recognized for preventing catastrophic failures and protecting organizational assets.

This psychological shift ripples outward through entire organizations. Operations managers sleep better knowing that critical assets are monitored around the clock. Financial teams appreciate the predictability that comes from scheduled maintenance rather than emergency repairs with their premium costs and unpredictable timing. Even frontline workers feel safer knowing that the equipment around them is continuously checked for dangerous deterioration. The vibration sensor becomes a tool not just for mechanical monitoring but for organizational confidence—a foundation upon which better decisions, clearer communication, and stronger cultures are built. It creates transparency that allows different departments to understand equipment health in ways that were previously accessible only to maintenance specialists with decades of experience.

How Modern Vibration Sensing Technology Creates Actionable Intelligence

The technical evolution of vibration sensors tells a story about our growing sophistication in translating physical phenomena into digital insight. Early sensors were simple accelerometers that measured movement intensity without much discrimination. Modern systems like vibration sensor technologies from leading manufacturers represent something far more nuanced—devices that don’t just detect vibration but interpret it, filtering signal from noise, distinguishing between normal operation and concerning anomalies. These advanced systems incorporate signal processing capabilities that would have required dedicated analysis equipment in previous generations, now packaged into compact sensors that can be deployed throughout facilities.

What makes contemporary vibration sensors particularly powerful is their ability to operate autonomously at the edge, making intelligent decisions about what requires human attention and what doesn’t. This matters because the real challenge in industrial monitoring has never been collecting data—it’s been making that data meaningful. A sensor that screams alerts for every minor variation trains teams to ignore warnings, creating dangerous alert fatigue. A system that only flags genuine concerns becomes trusted, integrated into workflows, genuinely transformative. The difference between these outcomes often comes down to how well sensors are configured and how thoughtfully their capabilities match the specific monitoring requirements of different equipment types and operating environments.

Selecting Sensors That Match Your Equipment’s Unique Signatures

Different machines require different monitoring approaches, and understanding this reveals deeper truths about industrial diversity. A high-speed turbine spinning at thousands of RPM generates vibration patterns completely unlike a slow-speed conveyor belt. Temperature extremes, mounting constraints, power availability, communication requirements—each variable shapes what type of sensor makes sense. The decision process mirrors broader life choices: one-size-fits-all solutions rarely work optimally, while thoughtful matching of tools to specific needs creates excellence. This customization requirement means that successful vibration monitoring implementations begin with careful assessment of equipment characteristics, operating conditions, and organizational capabilities rather than simply purchasing whatever sensors seem popular or inexpensive.

Sensitivity ranges determine whether sensors can detect both subtle early warnings and dramatic fault conditions without saturating at either extreme. Frequency response defines which vibration patterns the sensor can accurately capture—critical because different failure modes manifest at different frequencies. Bearing defects typically show up in specific frequency ranges, while imbalance issues appear in others. Housing and environmental ratings ensure sensors survive the harsh conditions of industrial environments, from chemical exposure to extreme temperatures to the physical abuse of mounting on equipment that shakes, vibrates, and experiences thermal cycling. These aren’t just specifications to check off; they’re design choices that reflect understanding of real-world complexity and respect for the challenges maintenance teams actually face in keeping production running.

Modern sensors also incorporate features that simplify installation and commissioning, recognizing that ease of deployment directly impacts how widely organizations can extend monitoring coverage. Auto-configuration capabilities, self-learning baseline establishment, and intuitive setup interfaces reduce the specialized expertise required to expand monitoring systems. Reviewing detailed sensor specifications helps teams understand sensor capabilities, installation requirements, and optimal configuration approaches, making sophisticated monitoring accessible to organizations without extensive vibration analysis expertise on staff.

Integration Points That Transform Data Into Organizational Wisdom

The most sophisticated sensor becomes merely an expensive paperweight if it can’t communicate its findings effectively. Modern industrial protocols—IO-Link, Ethernet/IP, Modbus—represent more than technical standards; they’re agreements about how systems should speak to each other, enabling interoperability that was impossible in previous generations. When vibration data flows seamlessly into SCADA systems, maintenance management software, and analytical platforms, it becomes part of an organization’s nervous system rather than an isolated data point. This connectivity enables the holistic view of equipment health that drives truly proactive maintenance strategies.

This integration capability transforms how decisions get made throughout organizations. Maintenance managers can track degradation trends across entire facilities from central dashboards, identifying patterns that reveal root causes affecting multiple machines. Operators receive real-time alerts on their mobile devices when conditions warrant attention, enabling rapid response without requiring constant manual monitoring. Historical data enables root cause analysis that reveals patterns invisible in individual incidents, helping teams understand whether failures stem from operational practices, environmental factors, or equipment design limitations. The vibration sensor evolves from a monitoring device into a knowledge generation system, continuously teaching organizations about their equipment’s behavior and optimal care requirements.

Building Maintenance Cultures That Prevent Rather Than React

Perhaps the deepest transformation vibration sensors enable isn’t technical but cultural. Organizations that embrace continuous monitoring gradually shift from firefighting to prevention, from crisis response to strategic asset management. This transition requires more than installing hardware—it demands new mindsets, revised workflows, and genuine leadership commitment to proactive approaches. The cultural change challenges long-established patterns where maintenance teams derived status from heroically fixing emergencies rather than preventing them, where production pressures encouraged running equipment until failure rather than scheduling preventive interventions.

Teams trained to react to breakdowns must learn to interpret trending data and schedule interventions before failures occur. The skills required shift from emergency repair expertise toward analytical thinking and planned project management. Some find this transition uncomfortable, missing the adrenaline of crisis response and the immediate gratification of fixing broken equipment. Others discover renewed purpose in preventing problems rather than merely fixing them, finding satisfaction in the evidence that their proactive work averted potential disasters. Smart organizations recognize this change represents growth—evolution toward more sustainable, less stressful, ultimately more rewarding ways of working that extend careers by reducing the physical and emotional toll of constant emergency response.

The Economic Reality of Proactive Equipment Management

The financial case for vibration monitoring extends far beyond avoiding catastrophic failures, though those savings alone often justify investment. Consider the cascading costs of unplanned downtime: lost production, expedited parts shipping, premium labor rates for emergency repairs, potential safety incidents, quality issues from equipment operating in degraded conditions, and customer relationship damage from missed commitments. Single incidents frequently cost more than comprehensive monitoring systems. When you factor in the opportunity costs—contracts lost because capacity wasn’t available, markets ceded to competitors who could deliver reliably—the true expense of reactive maintenance becomes staggering.

More subtly, predictive maintenance enables optimization impossible under reactive approaches. Maintenance gets scheduled during planned shutdowns, maximizing equipment availability during critical production periods. Parts get ordered with normal lead times rather than air-freighted at multiples of standard cost. Technicians work planned shifts rather than around-the-clock emergencies that disrupt personal lives and drive turnover. Over time, these efficiencies compound, creating financial advantages that separate industry leaders from struggling competitors who remain trapped in reactive cycles.

Creating Sustainable Systems That Evolve With Your Organization

The most successful vibration monitoring implementations start focused and expand strategically. Organizations often begin with their most critical assets—machines where failures create the greatest consequences—then gradually extend coverage as they build competence and demonstrate value. This evolutionary approach respects that technology adoption is fundamentally a human process requiring learning, adjustment, and cultural acceptance. It allows teams to develop proficiency with smaller-scale systems before expanding to facility-wide deployments.

As monitoring systems mature, they become platforms for continuous improvement. Alert thresholds get refined based on operational experience. New analytical techniques reveal insights invisible in initial implementations. Integration with other systems creates synergies that multiply value. The vibration sensor network transforms from a project into an asset, continuously delivering returns and enabling capabilities that seemed impossible before implementation.

Moving Forward With Confidence and Clarity

Choosing to implement comprehensive vibration monitoring represents more than a maintenance decision—it’s a statement about organizational values and operational philosophy. It declares that prevention matters more than reaction, that data-driven decisions surpass guesswork, that investing in reliability creates value beyond immediate returns. For the engineers and managers considering this path, the question isn’t merely whether vibration sensors work—extensive evidence proves they do—but whether your organization is ready to embrace the cultural shifts that make them truly transformative.

The journey from reactive maintenance to predictive reliability won’t happen overnight, and it won’t always feel comfortable. But for those willing to persist through implementation challenges and trust in systematic approaches over crisis response instincts, the destination offers something valuable: operations characterized by confidence rather than anxiety, by strategy rather than panic, by continuous improvement rather than perpetual firefighting.