Now Reading: Rolling Forward: Innovative Applications and Safety Tips for Casters in Modern Industries

-

01

Rolling Forward: Innovative Applications and Safety Tips for Casters in Modern Industries

Rolling Forward: Innovative Applications and Safety Tips for Casters in Modern Industries

Why Casters Matter in Industrial Mobility

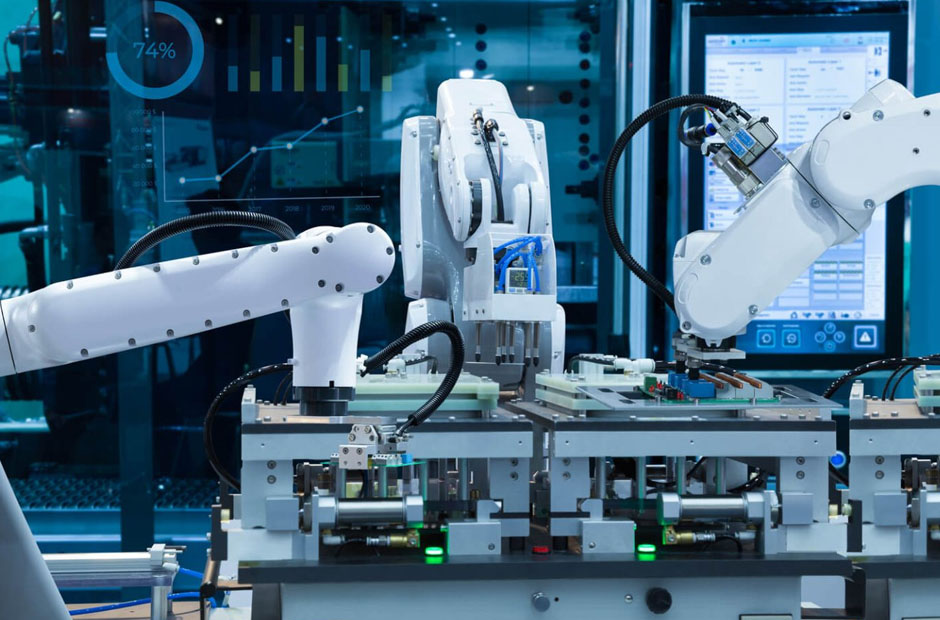

The strategic use of casters can lower manual handling risks, support lean manufacturing principles, and keep operations agile. As industries embrace automation and last-mile logistics, durable caster systems ensure that everything from robotics to medical beds glides smoothly through various environments. In the age of global logistics growth, the right caster choice is a smart, scalable investment in workplace productivity.

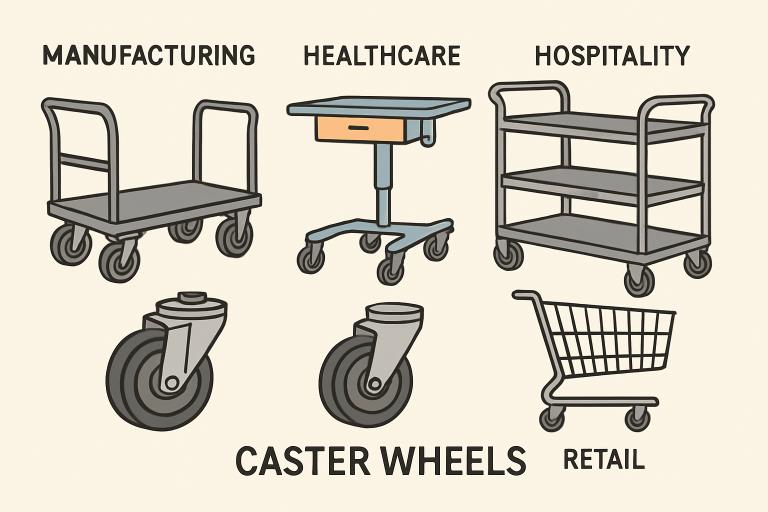

Casters remain an unsung hero in modern industry, quietly ensuring the seamless movement of heavy loads, machinery, and workstations. From complex production lines and bustling warehouses to demanding hospital environments, casters enable swift adaptation and reconfiguration for efficiency. Among the many options available today, swivel casters stand out for their versatility, allowing for tight turns and easy maneuvering in confined spaces—critical in settings where space and time are at a premium.

Creative Uses for Casters Across Industries

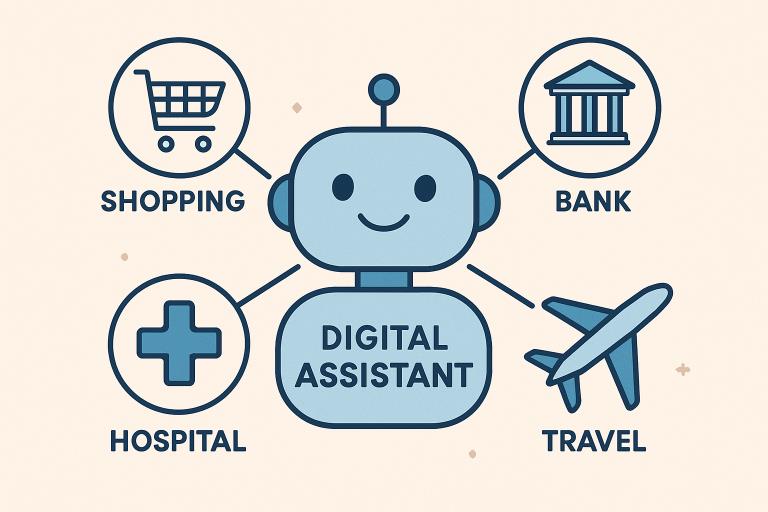

Innovation in industrial design has expanded casters’ roles beyond carts. In healthcare, advanced casters move diagnostic equipment and mobile workstations smoothly, lowering damage risk. The hospitality sector uses casters for mobile serving stations and adjustable displays that adapt spaces. Retailers rely on casters for display fixtures to quickly reconfigure store layouts for seasonal or promotional needs. In high-tech manufacturing, anti-static casters prevent static discharge, safeguarding electronics—highlighted in recent reports on automation and workplace trends. These examples show how casters help create safer, more flexible workspaces.

How to Choose the Right Caster for the Job

Selecting the right casters is crucial for safety and performance. Choose wheels with varying load capacity, such as rubber for noise reduction, polyurethane for resilience, or steel for heavy loads. Assess the surface conditions to ensure optimal operation. Swivel or rigid casters can provide agile navigation in tight spaces, while careful selection ensures operational efficiency, prevents costly injuries, and supports ergonomics standards.

Safety Tips for Using and Maintaining Casters

Regular inspections are crucial for identifying damage or debris on wheels. Ensure all caster assemblies are tightened and lubricated for smooth rotation. Replace damaged or misshapen casters immediately to prevent accidents and maintain reliability. Train employees in safe maneuvering techniques for handling heavy loads. Regular caster care reduces workplace hazards, extends equipment life, and prevents workflow disruptions.

Emerging Caster Technologies and Materials

Advancements in caster manufacturing prioritize more than just load-bearing capabilities. Today’s casters feature innovations such as shock-absorbing designs to protect both wheels and cargo, anti-static materials for static-sensitive workplaces, and non-marking tires to safeguard pristine flooring. Manufacturers are also experimenting with high-durability polymers and corrosion-resistant finishes, enabling casters to perform reliably in food processing, chemical manufacturing, and outdoor environments. These technologies make it easier to tailor caster selection to unique business needs and industry standards.

Cost Savings and Productivity Benefits

While often a smaller line item on equipment budgets, casters have an outsized impact on operational efficiency and cost control. Well-engineered casters reduce downtime by preventing frequent breakdowns or damage to flooring. They also decrease the risk of workplace injuries linked to faulty or hard-to-maneuver equipment. Over time, these factors translate into measurable savings and higher productivity rates, making the case for investing in premium caster solutions, which are especially strong for busy, resource-conscious organizations.

Common Caster Challenges and Solutions

Industrial and commercial settings pose unpredictable challenges—from uneven surfaces to chemical exposure and frequent reconfiguration. Best practices include establishing regular caster maintenance checklists, training staff on proper usage, and keeping spare units on hand for immediate replacement. In sectors such as food service and chemical processing, corrosion-resistant or sealed casters help combat the effects of harsh cleaning agents and spills. Proactively addressing the most common hurdles ensures safety and operational continuity even in the most demanding workplaces.

Conclusion: Smart Wheels, Smart Workplaces

The impact of casters extends far beyond easy movement—they are fundamental to modern operational success across multiple industries. From supporting patient care in hospitals to driving the flexibility of manufacturing and retail layouts, casters are a quiet yet powerful catalyst for efficiency and adaptability. By staying informed about the latest advancements and best safety practices, businesses can make savvy decisions that keep their facilities rolling smoothly for years to come.