Now Reading: 4 Ways Expert Support Maximizes Long-Term Equipment Performance

-

01

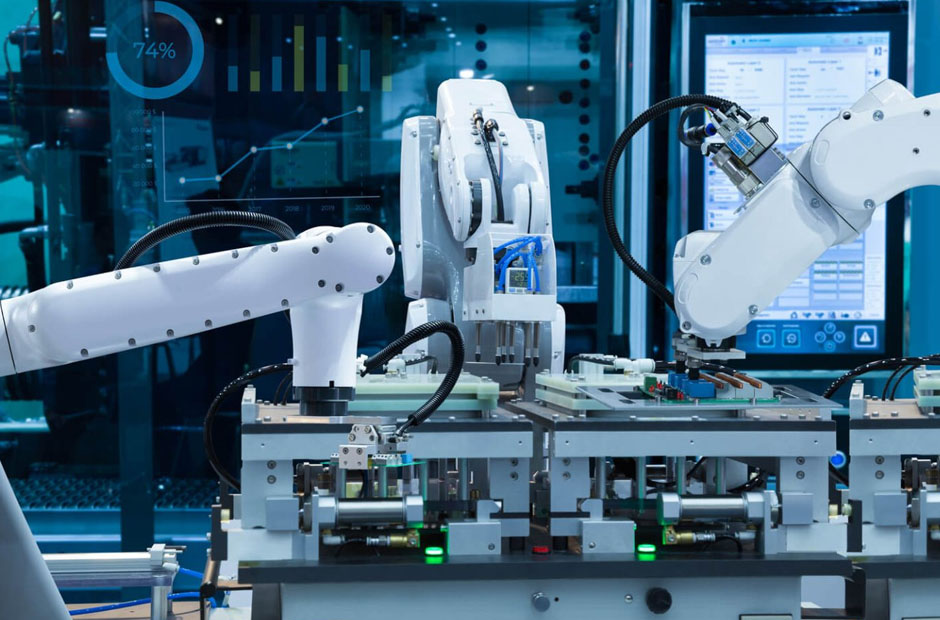

4 Ways Expert Support Maximizes Long-Term Equipment Performance

4 Ways Expert Support Maximizes Long-Term Equipment Performance

Investing in high-quality industrial equipment is a significant financial commitment for any business. To maximize this investment, it’s crucial to look beyond the initial purchase and focus on long-term performance and reliability. Just like a high-performance vehicle requires regular tune-ups from a skilled mechanic, your heavy-duty equipment needs consistent, expert care to operate at its best. Neglecting this can lead to unexpected downtime, costly repairs, and a shorter operational lifespan.

Understanding the factors that contribute to equipment longevity can transform your maintenance strategy from a reactive necessity into a proactive asset. This article explores four essential ways that expert support and strategic maintenance can help you get the most out of your machinery for years to come. By prioritizing these areas, you can ensure your equipment remains a productive and reliable cornerstone of your operations.

1. Implement a Proactive Maintenance Schedule

Waiting for a piece of equipment to break down before giving it attention is one of the costliest mistakes a business can make. A proactive maintenance schedule, guided by manufacturer recommendations and expert insights, is the key to preventing minor issues from becoming major failures. This approach involves regularly scheduled inspections, fluid analysis, and component checks designed to identify and address potential problems early.

For instance, routine oil and filter changes are simple yet vital for engine health. Dirty oil can cause excessive wear on critical components, leading to reduced efficiency and eventual failure. A study by the Equipment Leasing and Finance Association found that disciplined preventive maintenance can reduce overall repair costs by as much as 25%. By adhering to a consistent schedule, you not only extend the life of your machinery but also maintain its performance and fuel efficiency. This systematic approach ensures that every part of your equipment, from the engine to the hydraulic systems, operates within its optimal parameters, minimizing the risk of unexpected and expensive downtime.

2. Utilize Genuine Parts and Components

When it comes to repairs and replacements, the parts you choose matter immensely. While aftermarket parts may seem like a cost-effective solution, they often fall short of the quality and precise specifications of Original Equipment Manufacturer (OEM) parts. Genuine parts are designed and tested by the same engineers who built your equipment, guaranteeing a perfect fit and optimal performance. Using non-genuine components can lead to compatibility issues, increased wear and tear, and even catastrophic failures that could have been easily avoided.

Consider the intricate workings of a fuel injection system. An OEM injector is calibrated to deliver the exact amount of fuel at the precise moment required for peak combustion. An aftermarket part might not meet these strict tolerances, resulting in poor fuel economy, increased emissions, and potential damage to the engine over time. Sticking with genuine parts ensures that your equipment maintains its original performance standards and that all components work together harmoniously, preserving the integrity and longevity of your investment.

3. Rely on Advanced Diagnostic Technology

Modern industrial equipment is more complex than ever, integrated with sophisticated electronic control units (ECUs) that monitor and manage every aspect of performance. When a problem arises, pinpointing the root cause requires more than just a visual inspection. This is where advanced diagnostic technology becomes indispensable. Expert technicians use specialized diagnostic tools to connect directly to the equipment’s onboard computer, allowing them to read error codes, monitor live data, and quickly identify malfunctions that would otherwise be hidden.

This level of precision is particularly important for complex systems. For example, a modern engine might have dozens of sensors monitoring everything from exhaust temperature to crankshaft position. A fault in any one of these can impact performance. Diagnostic tools can isolate the faulty sensor in minutes, saving hours of manual troubleshooting and preventing unnecessary parts replacement. Leveraging this technology ensures that repairs are accurate and efficient, getting your equipment back in service faster and preventing recurring issues. When seeking a professional diesel engine service, ensuring they use up-to-date diagnostic equipment is critical for effective and reliable maintenance.

4. Invest in Continuous Operator Training

The person operating the equipment plays a significant role in its long-term health. Improper operation—such as aggressive acceleration, overloading, or ignoring warning indicators—can place unnecessary stress on the machine’s components, leading to premature wear and failure. Providing operators with thorough and ongoing training is a powerful way to foster a culture of care and responsibility that directly translates to improved equipment longevity.

A well-trained operator understands the machine’s capabilities and limitations. They know the importance of daily walk-around inspections to check for leaks, loose bolts, or other visible issues before starting work. They also recognize the meaning of different dashboard alerts and know when to shut down the machine to prevent further damage. According to industry reports, effective operator training can reduce unscheduled maintenance by up to 30% and extend the life of major components significantly. Investing in your team’s knowledge not only protects your physical assets but also enhances safety and productivity across your entire operation.