Now Reading: The Secret to Seamless Edges in Large-Scale Production

-

01

The Secret to Seamless Edges in Large-Scale Production

The Secret to Seamless Edges in Large-Scale Production

Key Takeaways

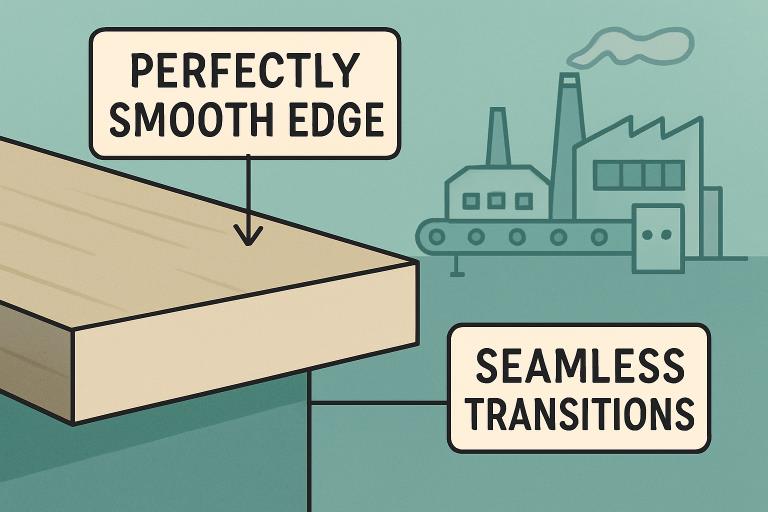

- Seamless edges are crucial to the durability and aesthetics of products across industries such as furniture, metal fabrication, and packaging.

- Technological innovations, including intelligent machining units and 3D edgebanding, have improved efficiency and consistency in edge processing.

- Eco-friendly solutions and advanced cutting systems are shaping a more sustainable and higher-quality production landscape.

- Implementing best practices and investing in training are vital steps for achieving flawless edges in mass manufacturing.

Understanding the Importance of Seamless Edges

In modern manufacturing, seamless edges are more than a hallmark of precision—they define the quality, longevity, and visual appeal of finished products. From cabinetry to metalwork, achieving a flawless edge prevents defects such as moisture penetration and sharp burrs, ensuring the end product performs reliably and appears sophisticated in any setting. Companies around the world are investing in innovative machinery, such as an industrial edge banding machine, to achieve this level of perfection at scale.

Whether working with wood, metals, or composite materials, seamless edges provide critical functional benefits. In the world of furniture, for example, properly sealed and banded edges create a formidable barrier to water and dust. In contrast, in packaging and automotive manufacturing, high-quality edges can prevent injuries and mechanical inefficiencies.

The demand for these smooth transitions has driven manufacturers to rethink traditional processes and methods, giving rise to a landscape driven by advanced automation and meticulous quality control. This shift not only enhances output but also positions manufacturers to address increasingly discerning customer expectations.

Emphasizing seamless edge production also means addressing regulatory standards and environmental considerations, which have become increasingly stringent in recent years. In tightly regulated markets, lush, even edges can be the difference between regulatory compliance and costly product recalls.

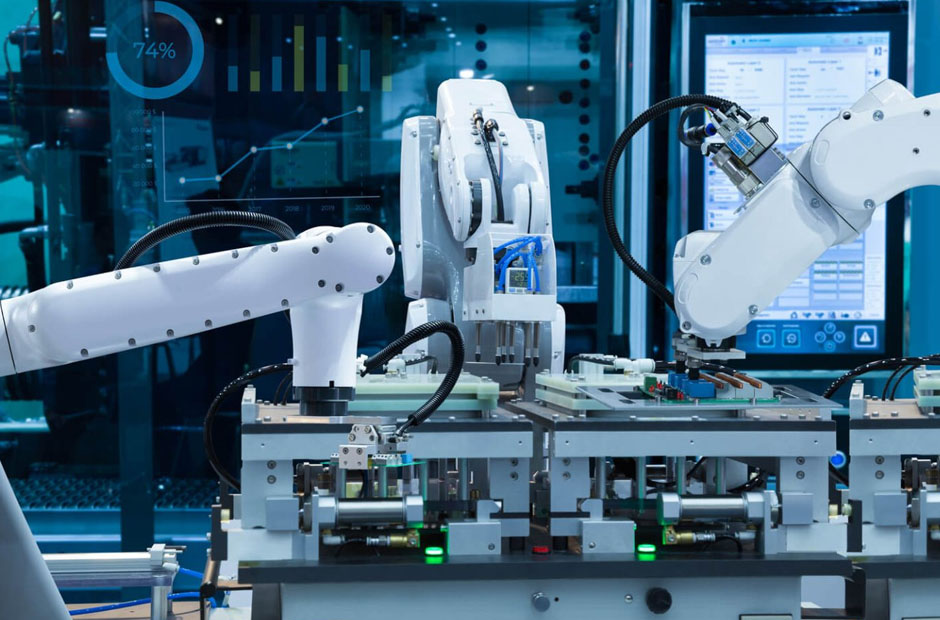

Innovations in Edge Processing Technologies

Breakthroughs in edge processing have reshaped large-scale manufacturing. The introduction of universal machining units, such as those pioneered by IMA Schelling, enables simultaneous drilling and milling with edge application. This reduces the need for multiple setups and fosters a streamlined workflow, resulting in not just faster turnaround but also improved accuracy across all production lines.

These advancements have opened new design opportunities. Handleless cabinet fronts and custom-built panels with complex edge profiles are now produced with a high degree of repeatability, meeting designer and architect specifications more precisely than ever.

Advancements in Edgebanding Techniques

Automatic edgebanding machines have redefined how companies achieve seamless finishes on a wide range of substrates. 3D edgebanding takes things further by adding layers of implication and depth, enriching surfaces with both tactile and visual depth.

New edgebanding technology has also brought about substantial improvements in energy efficiency and labor optimization. These systems automatically regulate adhesive application, substrate handling, and finishing—delivering a reliable, high-quality result on every part, regardless of order size.

Origami-Inspired Deployable Structures

The quest for seamlessness extends beyond traditional flat surfaces. Inspired by origami, researchers have created deployable structures that transform from compact blocks into large, continuous surfaces without visible seams. These intricate systems, first encountered in experimental architecture and portable shelters, are being adapted for manufacturing, where their space efficiency and seamless finishes offer significant advantages.

Origami-based deployable mechanisms are also being introduced in industries that require rapid on-site assembly, such as aerospace and disaster relief, underscoring the broad impact of seamless design thinking.

Enhancing Edge Quality in Metal Fabrication

Metal fabrication greatly benefits from advancements such as the TruLaser Series 3000 Bevel Cut Edition, which automatically creates beveled edges and enables workers to achieve various edge profiles suited for welding, assembly, or finish work. Automatic edge geomorphology not only reduces preparation time but also ensures each piece fits perfectly, eliminating rework and waste.

Such innovation highlights how edge technology has moved beyond aesthetics to deeply influence operational efficiency and overall assembly quality in sectors ranging from automotive to construction.

Eco-Friendly Edgebanding Solutions

As sustainability becomes central to the manufacturing conversation, eco-friendly edgebanding solutions are on the rise. Manufacturers are embracing adhesives made from renewable resources, solvent-free application processes, and edge materials that are recyclable or compostable. These changes help reduce the industry’s carbon footprint and meet strict environmental standards.

The integration of green manufacturing not only boosts a company’s reputation but also appeals to a growing segment of environmentally conscious consumers and clients.

Implementing Seamless Edge Techniques in Your Production

Assess Current Processes

Begin by thoroughly evaluating your existing edge processing operations. Identify any pain points relating to efficiency, quality, or safety. Bring in external specialists if necessary to benchmark current performance against advanced industry norms.

Invest in Advanced Machinery

New technology, such as automatic edgebanders and hybrid machining units, can significantly enhance the consistency and quality of your edge work. These machines reduce the manual intervention required and deliver precision across wide production runs.

Train Personnel

To maximize the return on your equipment investments, employees must receive extensive training in both the operation and maintenance of these systems. As equipment becomes more complex, ongoing professional development ensures that your workforce keeps pace with technological advancements.

Monitor Quality Control

Implement stringent, multi-step quality control processes emphasizing both appearance and structural integrity. Use state-of-the-art inspection systems to catch issues early and maintain high standards throughout every batch.

Conclusion

Seamless edges have become synonymous with sophistication, longevity, and performance in modern manufacturing. With advances in edgebanding technology, machining units, origami-inspired designs, and sustainable materials, today’s manufacturers can achieve unrivaled edge finishes—even at scale. By committing to continuous improvement and leveraging the best available resources, companies can position themselves at the forefront of their industries and deliver products that exceed both regulatory requirements and customer expectations.