Now Reading: Choosing the Right Industrial Supplies for Long-Term Use

-

01

Choosing the Right Industrial Supplies for Long-Term Use

Choosing the Right Industrial Supplies for Long-Term Use

Key Takeaways

- Carefully assess operational needs before investing in industrial supplies.

- Prioritize quality and supplier reliability over initial cost.

- Factor in energy efficiency, safety standards, and new technology for long-term benefits.

- Evaluate the total cost of ownership, not just the purchase price.

Choosing the right industrial supplies is a critical decision for businesses aiming to maintain long-term efficiency, safety, and cost-effectiveness. With the wide variety of equipment, tools, and materials available today, selecting products that offer durability and consistent performance can significantly reduce downtime and operational costs. It’s important to evaluate not only the immediate needs of your facility but also the long-term implications of your choices, including maintenance requirements, compatibility with existing systems, and overall lifecycle value. Thoughtful selection ensures that operations run smoothly and that investments in supplies deliver lasting benefits.

When sourcing industrial products, it’s helpful to be aware of major industrial suppliers in North Carolina, as they often offer a broad range of options and support services tailored to diverse industry needs. By carefully assessing supplier reliability, product quality, and service capabilities, businesses can make informed decisions that support sustainable operations while minimizing the risk of costly replacements or interruptions.

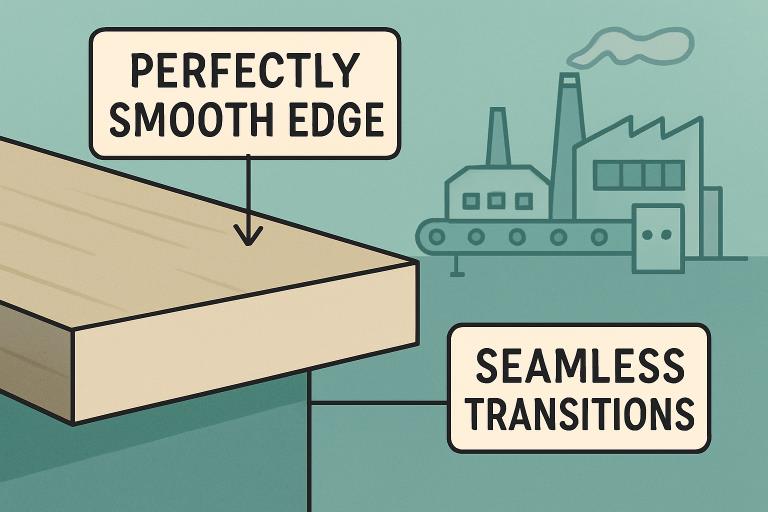

Understanding Your Operational Needs

The first step in choosing effective industrial supplies is to thoroughly assess your operational requirements. This involves analyzing the scope of your work, the types of materials processed, expected workload, and environmental conditions such as humidity, temperature, and exposure to corrosive materials. A detailed evaluation helps to pinpoint the specifications and performance standards needed for your unique situation, ensuring a seamless workflow and minimal risk of equipment incompatibility.

Consult your production and maintenance teams for input on current challenges and pain points. Reviewing recent maintenance logs will help you identify recurring issues and anticipate the capabilities your next purchase should deliver. An open dialogue between stakeholders will help bridge the gap between actual needs and expectations.

Prioritizing Quality Over Cost

Cutting corners on quality to minimize upfront expenses often leads to costlier consequences down the road. Subpar industrial products are prone to early failure, leading to frequent repairs, lost productivity, and higher long-term costs. By contrast, reputable brands and high-quality supplies deliver reliable performance and significantly extend equipment lifespans, helping you avoid emergency repairs and production bottlenecks.

To make the most of your budget, evaluate product reviews, warranty terms, and total cost-of-life-cycle data. This proactive approach can help prevent unexpected expenses and reinforce health and safety protocols.

Evaluating Supplier Reliability

Selecting a reliable supplier is just as important as choosing the right products. Dependable suppliers maintain stringent quality control standards, adhere to industry certifications, and offer clear documentation on their manufacturing practices. Before committing to any supplier, consider conducting site visits, requesting references, and reviewing independent audits.

Long-standing industry relationships often signal stability, trustworthiness, and a proven record for meeting deadlines. Supplier responsiveness also plays a major role in your operational continuity. Choosing a partner with a history of timely delivery and support will reduce disruptions and enhance your business’s resilience.

Considering Energy Efficiency

Energy-efficient industrial supplies are vital for minimizing operational costs and supporting sustainability goals. Look for products with energy-saving certifications or features such as low-power standby modes, high-efficiency motors, and programmable controls. Over time, these enhancements reduce both your environmental footprint and energy expenses.

Many industries now report on sustainability as part of their corporate responsibility agenda, making efficient equipment essential for compliance and for managing reputation. Improved efficiency not only offers savings but can also support competitive differentiation in the marketplace.

Ensuring Compliance with Safety Standards

Workers’ safety is paramount when selecting new equipment or materials. Always verify that supplies comply with OSHA or other relevant industry safety regulations. Safety features such as emergency shut-offs, protective housing, and enhanced user controls indicate well-designed products that prioritize worker protection.

Review inspection and certification records before making purchases, and ensure your team is trained in proper use and maintenance. A robust safety culture reduces incident rates and strengthens your company’s compliance posture.

Assessing Total Cost of Ownership

The purchase price is just one component of the total cost of ownership for industrial supplies. Consider ongoing maintenance, repair costs, spare parts availability, training requirements, and anticipated downtime. Investing more upfront often dramatically reduces your lifetime equipment expenses by reducing breakdowns and increasing productivity.

Work with suppliers to access service packages or extended warranties that further protect your investment. Documenting the complete lifecycle costs enables wiser, data-driven decision-making that benefits your organization in the long term.

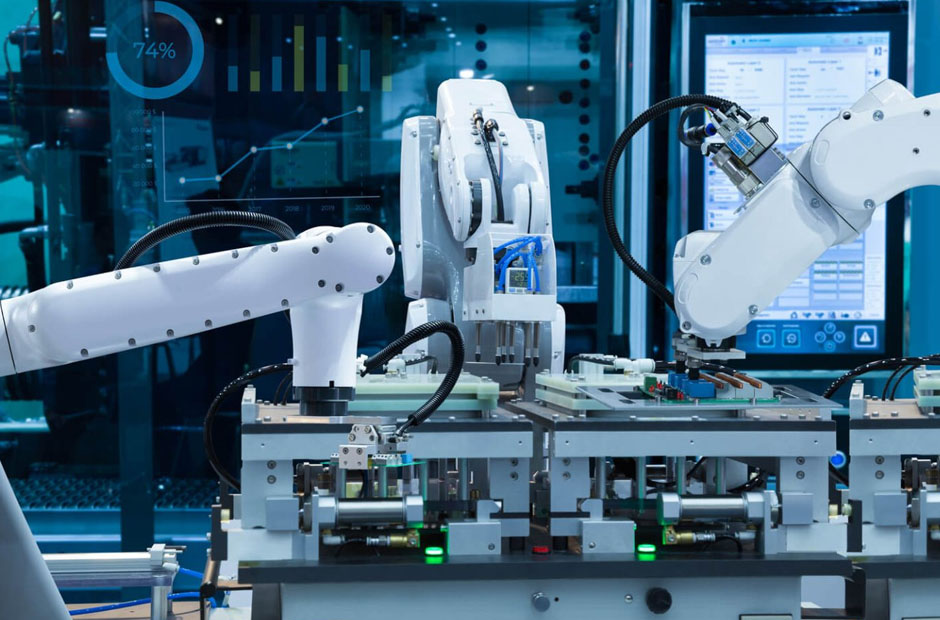

Exploring Technological Advancements

Staying current with emerging technology can yield major operational advantages. Advances such as industrial IoT sensors, automated data analytics, and inventory management systems help streamline processes and minimize human error. For example, next-generation vending solutions equipped with smart tracking features enable automatic stock replenishment and improved inventory visibility.

Integration of new tech can facilitate proactive maintenance strategies, support compliance tracking, and enhance workplace safety. Keeping pace with innovation ensures your company benefits from the most efficient and resilient infrastructure available.

Conclusion

Selecting the right industrial supplies for long-term use requires a balance of upfront assessment, supplier vetting, commitment to quality, and attention to safety and efficiency standards. Factor in long-term costs, evaluate the available technology, and involve key stakeholders in the decision-making process for the best results. Thoughtful investments ensure your operations remain productive, safe, and cost-effective in an ever-evolving industrial landscape.