Now Reading: Digital Connectivity Trends in Modern Manufacturing

-

01

Digital Connectivity Trends in Modern Manufacturing

Digital Connectivity Trends in Modern Manufacturing

Key Takeaways

- Private 5G provides secure, high-speed, and low-latency connectivity, enabling automation and intelligent workflows in even the most demanding manufacturing environments.

- IIoT underpins real-time data visibility, supporting predictive maintenance, optimized production, and data-driven decision-making at every stage of manufacturing.

- AI enhances manufacturing through advanced analytics, enabling process optimization and providing scalable, actionable insights across the entire supply chain.

- XR technologies help bridge the digital and physical processes for immersive employee training, remote assistance, and workforce collaboration in modern industrial facilities.

- Integrated, modular platforms eliminate operational silos, allowing for seamless data exchange and a unified, holistic view of production and performance.

Modern manufacturing is no longer defined solely by heavy machinery or manual assembly lines; it is now experiencing a full-scale digital revolution, one that is fundamentally transforming how products are designed, produced, and delivered. The global manufacturing landscape is evolving rapidly, driven by rising consumer expectations, increasingly complex supply chains, and a relentless push for efficiency. Amid this changing environment, manufacturers are embracing a diverse array of advanced connectivity solutions and emerging technologies that are shaping the future of industrial production. Secure, reliable manufacturing communication solutions have become the backbone of this transformation, enabling both real-time collaboration and automated workflows across every facet of an organization. Today, these solutions bridge gaps between physical shop floors and digital enterprise platforms, forming the robust foundation needed to support connected, scalable, and agile manufacturing environments.

These acceleration trends in digital connectivity are unlocking a host of new capabilities for manufacturers worldwide. With the adoption of private 5G wireless networks, broad deployment of the Industrial Internet of Things (IIoT), and the rapid integration of advanced tools such as Artificial Intelligence (AI) and Extended Reality (XR), manufacturers are now empowered to collect comprehensive real-time data, optimize intricate processes, and elevate both speed and product quality to unprecedented levels. Factories that leverage these interoperable connectivity platforms are not only more responsive to shifting market dynamics but also enjoy greater operational resilience in the face of disruptions. Embracing these advances enables businesses to streamline processes, enhance transparency across global sites, and ensure their supply chains can withstand unpredictability, while fostering a culture of continuous innovation throughout the entire manufacturing lifecycle.

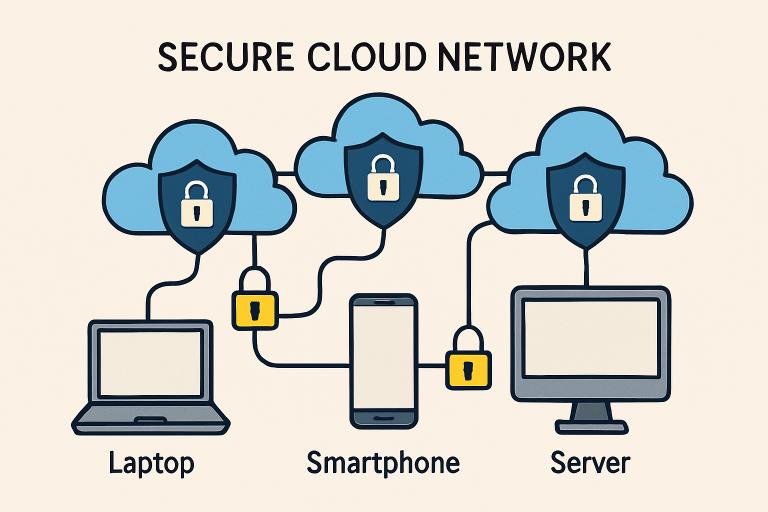

Private 5G Networks: A New Era of Connectivity

Private 5G networks represent a game-changing leap in industrial communication, offering manufacturers the scalability, speed, and ultra-low latency that traditional wireless solutions could never deliver. By deploying private 5G infrastructure, manufacturers create secure and controllable wireless environments tailored to their unique operational needs, supporting a vast array of connected machines, mobile robots, and sensor arrays throughout sprawling industrial campuses. This technology provides the backbone for large-scale automation, unrestricted mobility, and the seamless integration of intelligent machines, enabling real-time monitoring, sophisticated asset tracking, and remote maintenance capabilities that are critical for next-generation manufacturing.

The rapid pace of private 5G adoption is being driven in part by a surge in demand for smart factories and an increasing reliance on AI-powered automation. Global investment in private 5G is expected to grow exponentially as more manufacturers recognize the value of secure networks capable of handling mission-critical communications in real-time. The strategic benefit of this connectivity is clear: factories with private 5G infrastructure can automate intricate processes, adapt swiftly to fluctuations in customer demand, and respond proactively to production anomalies, creating a significant competitive advantage over slower-moving peers.

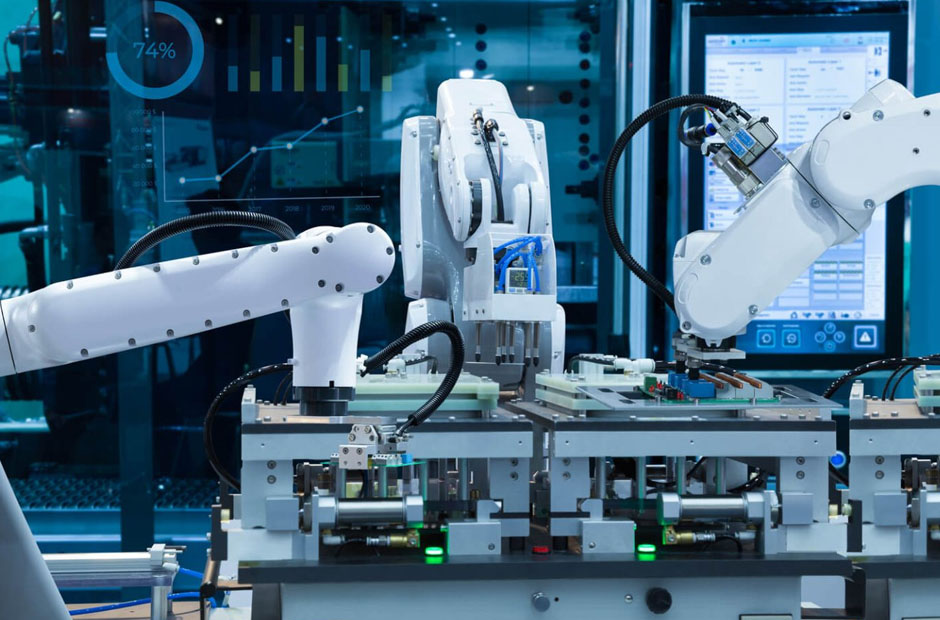

Industrial Internet of Things (IIoT): Enhancing Data Utilization

Within the modern factory, the implementation of the Industrial Internet of Things (IIoT) signifies a major turning point in how operational data is captured, analyzed, and acted upon. IIoT involves a massive network of interconnected sensors, smart devices, and advanced controllers that collect and share real-time information from almost every part of the production environment—whether it’s monitoring energy usage, tracking inventory, or determining the exact operating conditions of essential equipment. By consolidating and analyzing these dynamic streams of data, manufacturers gain critical visibility into every stage of their operations, enabling them to identify inefficiencies, detect signs of impending equipment failures, and optimize resource utilization through intelligent, predictive maintenance strategies. The impact of IIoT is highlighted by the Forbes Tech Council, which notes that IIoT adoption is now crucial for real-time risk mitigation and data-driven plant management.

Smart factories are harnessing IIoT not just for incremental improvements, but for complete digital transformation. By leveraging IIoT-enabled platforms, manufacturers can continuously optimize workflows, automate quality controls, and enable sophisticated supply chain orchestration—all in real time. Insights derived from connected assets empower engineers and decision-makers to act quickly, reduce planned and unplanned downtime, and maximize returns on digital investments. Additionally, by providing proactive notifications and facilitating seamless compliance tracking, IIoT helps manufacturers ensure worker safety and adherence to regulatory standards.

Artificial Intelligence: Driving Operational Efficiency

The integration of Artificial Intelligence has ushered in an era of unprecedented operational efficiency and process automation within the manufacturing industry. AI-powered systems analyze large and varied data sets faster and more thoroughly than any human workforce could, uncovering hidden patterns, predicting demand surges, and even suggesting ways to improve everything from raw material procurement to final product design. Manufacturers deploy advanced machine learning algorithms not just for predictive analytics, but to enhance automated planning, dynamic resource allocation, and real-time anomaly detection that would otherwise be impossible with conventional approaches.

One of AI’s greatest contributions to manufacturing is its ability to reduce costs while enhancing quality and throughput. AI tools can rapidly pinpoint the underlying causes of production bottlenecks or machine slowdowns, delivering real-time recommendations for process adjustments that keep output running smoothly. AI-driven computer vision systems, for example, automate quality assurance by catching even the smallest defects at speeds far beyond human inspection capabilities. By consistently delivering accuracy and precision, AI ultimately supports faster market releases, more personalized product variants, and heightened customer satisfaction—the hallmarks of modern industry.

Extended Reality (XR): Bridging Physical and Digital Worlds

Extended Reality (XR), which encompasses Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR), is rapidly redefining workforce training and industrial collaboration. By leveraging immersive 3D simulations, manufacturers can now train employees in highly realistic virtual settings, thereby improving both knowledge retention and job confidence. These simulations enable workers to practice complex or hazardous tasks in a controlled digital environment, thereby reducing safety risks and eliminating costly downtime associated with traditional training methods. Meanwhile, AR overlays project interactive digital instructions onto real-world equipment, providing step-by-step guidance during maintenance or assembly, and enabling frontline workers to resolve issues more quickly and with greater accuracy.

The benefits of XR also extend to remote collaboration and troubleshooting. With the help of AR and MR, dispersed teams can share live visual data, consult with offsite experts, or even walk through virtual prototypes—all without ever being on the same continent. XR technologies also enable manufacturers to innovate more rapidly and adapt to new capability requirements, supporting everything from accelerated product launches to high-quality remote inspections. Ultimately, XR forms a bridge between human skills and digital intelligence, amplifying both productivity and creativity across the manufacturing sector.

Integrated, Modular Platforms: Breaking Down Silos

Legacy manufacturing systems were often hindered by fragmented software tools and disconnected information silos, making cross-functional collaboration and holistic analysis very challenging. The solution now lies in integrated, modular digital platforms that unify data from enterprise resource planning (ERP), manufacturing execution systems (MES), IIoT devices, and more into one flexible, holistic dashboard. These platforms allow for real-time visibility into every phase of production, equipping decision-makers with actionable insights that would otherwise be buried in isolated systems.

Adopting interoperable, modular platforms enables manufacturers to quickly reconfigure workflows in response to changing customer demands, unforeseen supply chain obstacles, or rapid technological advancements, thereby driving significant increases in operational agility. These platforms break down barriers between teams and departments, fostering a more collaborative and data-driven approach to continuous improvement. When information flows freely across departments, organizations are better positioned to adopt best practices, accelerate digital transformation initiatives, and ensure every part of the business is moving toward operational excellence.

Conclusion

The convergence of private 5G, IIoT, AI, XR, and integrated modular platforms is ushering in a new era of digital connectivity for the manufacturing industry. By investing in advanced manufacturing communication solutions and adopting leading-edge digital tools, manufacturers can consistently evolve to meet market challenges, optimize processes, and remain securely connected. Those who prioritize a forward-thinking connectivity strategy will not only boost efficiency and product quality but also lay the groundwork for ongoing innovation in the ever-competitive industrial landscape.