Now Reading: Enhancing Safety and Efficiency in Plant Decommissioning

-

01

Enhancing Safety and Efficiency in Plant Decommissioning

Enhancing Safety and Efficiency in Plant Decommissioning

Key Takeaways

- Comprehensive risk assessment and planning form the backbone of safe decommissioning operations.

- Modern technologies, from digital twins to predictive modeling, continually raise safety standards and drive project efficiency.

- Consistent adherence to both national regulations and international best practices fortifies public trust and legal compliance.

- Effective waste management strategies are central to reducing environmental and human health risks.

- The establishment of a safety-first culture drives accountability and protects all project participants.

As the global energy landscape evolves, the retirement of aging power facilities has become increasingly common. Navigating the process of power plant decommissioning requires a structured, multifaceted strategy to protect workers, surrounding communities, and the environment. Decommissioning involves not only physical dismantling but also meticulous attention to regulatory compliance, risk management, and waste handling, from the project’s inception to its completion.

Power plant decommissioning projects are significant undertakings that can span years and involve a broad array of technical, environmental, and community stakeholders. Integrating advanced planning approaches ensures transitions are not only safe but also minimize disruptions to both human health and local ecosystems.

Comprehensive Planning and Risk Assessment

Successful plant decommissioning relies on thorough planning, assessing risks from hazardous substances to structural stability. Hazard assessments guide demolition methods and safety measures. The U.S. Department of Energy utilizes “protected assumptions” to mitigate contamination risks, as exemplified by the West Valley Demonstration Project’s exemplary safety record. Teams carefully plan each decommissioning phase with contingencies, forming a strong foundation that maintains project integrity and reduces hazardous errors.

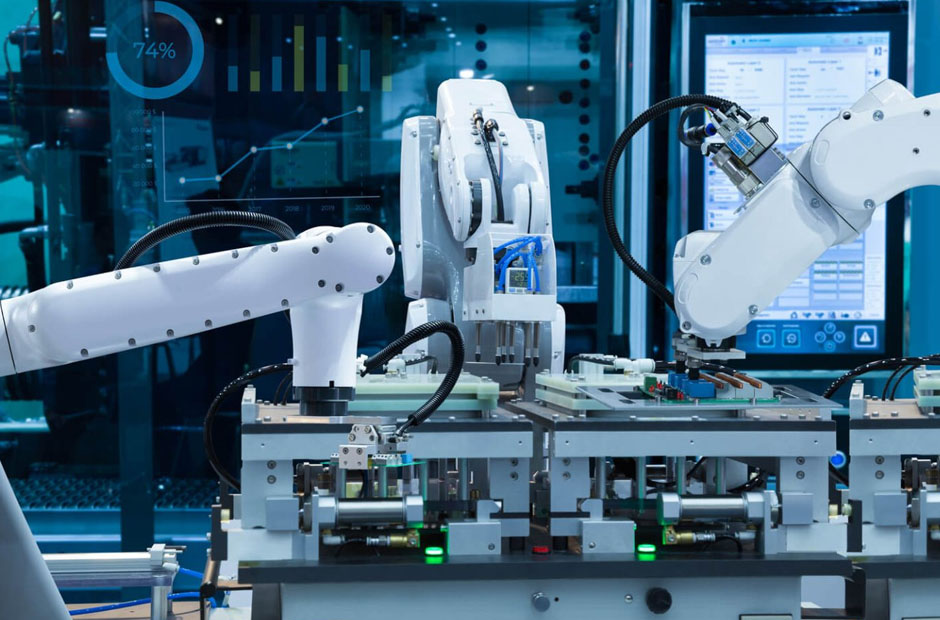

Leveraging Advanced Technologies

Modern decommissioning increasingly relies on digitalization and data-driven insights. The deployment of 3D modeling, digital twins, and virtual reality simulations equips project leads with the tools needed to plan intricate dismantling sequences while assessing various risk factors. The International Atomic Energy Agency (IAEA) highlights these advances as instrumental in improving efficiencies and reducing human error during facility retirement. Through scenario modeling, project managers can visualize outcomes and identify hazards in virtual environments before initiating any physical work, substantially decreasing exposure to hazardous environments and enhancing procedural precision. Technologies such as robotics further protect personnel by reducing the need for direct interaction with toxic or unstable materials.

Adhering to Regulatory Standards

Regulatory compliance is crucial during decommissioning. Laws such as the Clean Air Act and Clean Water Act establish emission limits; non-compliance can result in shutdowns and penalties. For example, Duke Energy’s closure of old units highlights the importance of pollution controls. Meeting or exceeding standards ensures legality, preserves reputation, and boosts public trust, especially when aligned with international standards. Clear documentation, routine audits, and ongoing communication with regulatory agencies further strengthen compliance. Companies that proactively adopt cleaner technologies also reduce long-term liabilities. Ultimately, staying ahead of evolving regulations supports smoother project execution and community confidence.

Effective Waste Management

Large-scale plant retirements generate significant waste, including hazardous materials such as asbestos, lead paint, metals, and radioactive substances. Effective decommissioning depends on correctly identifying, segregating, and disposing of these materials safely and responsibly. Examples like Lithuania’s Ignalina Nuclear Power Plant demonstrate that large volumes can be safely dismantled, with a significant amount of waste decontaminated for reuse, thereby reducing landfill waste and recovering resources. Waste management also emphasizes recycling, reuse, and detailed record-keeping to ensure compliance and traceability, aligning with sustainability efforts.

Fostering a Safety Culture

Beyond technical systems and procedures, a deeply ingrained safety culture is essential. Engaged leadership, regular training, and open communication ensure every employee is empowered to contribute to safety outcomes. Organizations like TRC Companies stress that intrinsic motivation across all staff levels leads to stronger compliance, fewer accidents, and heightened morale.

Proactive safety programs should encourage incident reporting, continuous improvement, and the integration of new safety innovations. Empowered workforces participate in hazard identification and take ownership of protective practices—creating safer workplaces and more efficient projects.

Conclusion

Plant decommissioning is a complex process that requires comprehensive oversight and a meticulous approach. By seamlessly integrating strong planning, technological innovation, rigorous regulatory adherence, and sound waste management within a fortified culture of safety, organizations can confidently navigate plant retirements. These strategies not only mitigate risk and reduce environmental footprints but also set the standard for responsible infrastructure transformation in the future.