Now Reading: Sustainable Practices in Plastic Extrusion

-

01

Sustainable Practices in Plastic Extrusion

Sustainable Practices in Plastic Extrusion

If you are in industries like automotive, construction, or solar paneling, your production may require minimizing environmental impact. The process of plastic extrusion involves handling large volumes of raw materials that require sustainable practices to reduce waste. Here are a few ways to implement sustainable practices in plastic extrusion:

Use Recycled Materials

When manufacturing companies use recycled materials in plastic extrusion, they reduce the need for new extraction. These companies may obtain recycled polymers for production or reprocess scrap material into a usable form. Some companies use polymers that are recyclable, like acrylonitrile butadiene styrene (ABS), which is corrosion-resistant. Extrusion companies may use polyethylene, which is also recyclable. Your business helps reduce the environmental impact by working with plastic extrusion companies that limit extraction.

Conserving raw materials in the extrusion process is a sustainable practice that helps to reduce pollution. Manufacturing companies can reduce water usage and carbon footprint by using recycled materials. When they use recycled materials in extrusion, they reduce the amount of waste that ends up in landfills.

Reduce Energy Consumption

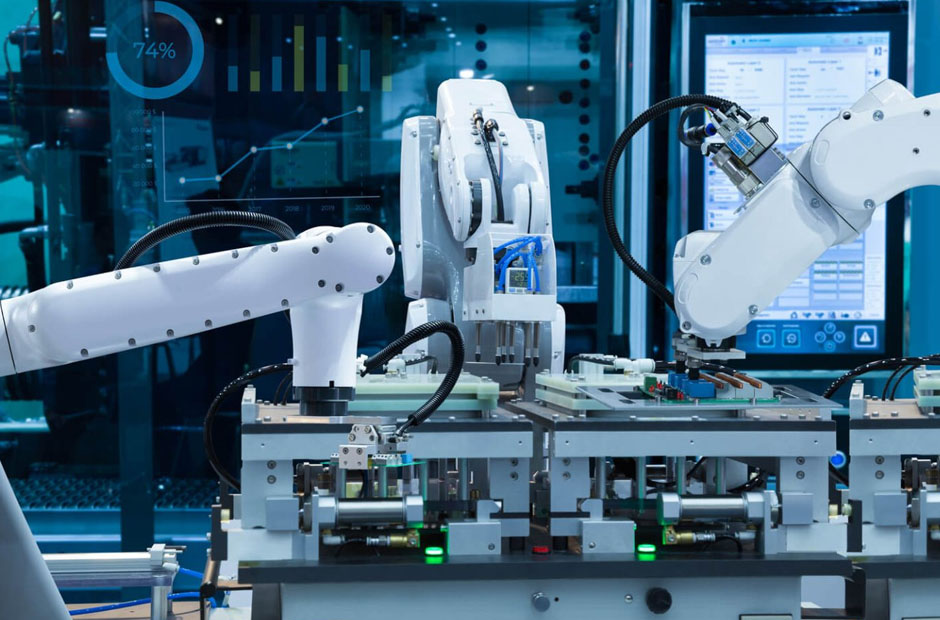

Producing energy from renewable sources such as solar panels or wind turbines may reduce the company’s carbon footprint. Energy efficiency is increased by using effective motors and other machine parts that are well-maintained. Reducing energy consumption in the extrusion process helps companies operate more efficiently.

To reduce energy consumption, extrusion companies should conduct regular maintenance checks and replace outdated or inefficient equipment. Insulating the equipment can also help reduce energy loss and improve efficiency. The companies are able to redirect the saved energy into other aspects of their business.

Minimize Material Waste

After producing plastic products, there may be leftover material that goes to waste. To minimize material waste, some extrusion companies adopt practices such as scrap reclamation systems or recycling programs. These systems and programs allow companies to reuse excess materials or recycle them into new products.

Extrusion companies may also conduct regular audits to identify areas of material waste; this helps them find ways of becoming more efficient. Companies should educate personnel on material handling and storage to preserve materials. When acquiring products, work with companies that use suppliers that offer environmentally friendly and sustainable materials.

Optimize Packaging Practices

At the end of the production process, packaging is used to protect and transport the final product. Packaging the products in an efficient and sustainable way helps extrusion companies reduce material waste. When designing packaging, companies may opt for minimal and lightweight options. Using packaging that fits the product closely reduces excess space. Companies can also streamline packaging by standardizing sizes, making it easier to use fewer materials while still maintaining protection.

Work With a Plastic Extrusion Company

Improving the extrusion process begins with choosing environmentally friendly methods that prioritize efficiency and long-term success. With a reliable plastic manufacturer, you are offered experience, advanced technology, and high-quality products. Your projects benefit from consistent production processes that reduce waste, optimize resources, and yield durable results. Work with a plastic extrusion manufacturer that prioritizes innovation and environmentally friendly methods.