Now Reading: The Role of Medical-Grade Plastics in Innovative Healthcare Solutions

-

01

The Role of Medical-Grade Plastics in Innovative Healthcare Solutions

The Role of Medical-Grade Plastics in Innovative Healthcare Solutions

Key Takeaways

- Medical-grade plastics are essential in healthcare due to their durability, biocompatibility, and cost-effectiveness.

- Biodegradable and sustainable plastics are helping reduce medical waste and environmental impact.

- Advanced manufacturing, including 3D printing and injection molding, enables the creation of personalized and high-precision medical devices.

- Plastics enhance patient safety by supporting single-use items and reducing the risk of infections.

- Regulatory standards ensure plastics are safe, non-toxic, and reliable for medical applications.

- Sustainability challenges are being addressed through the use of recyclable materials, green procurement practices, and closed-loop recycling programs.

- Personalized and smart plastic devices enhance patient outcomes and support the advancement of precision medicine.

- The medical-grade plastics market is growing, with innovations in eco-friendly, antimicrobial, and smart materials shaping the future of healthcare.

Introduction to Medical-Grade Plastics

Medical-grade plastics have fundamentally transformed the healthcare landscape. Their unique combination of durability, flexibility, and biocompatibility makes them essential for a wide range of medical devices and equipment, from everyday disposables like syringes to life-saving implants and diagnostic tools. The ability to withstand repeated sterilization, resist corrosion, and offer lightweight alternatives to metal or glass has propelled plastics into an indispensable role in clinics and hospitals worldwide. This reliability and versatility contribute to plastics being selected over other materials for many medical uses, particularly where hygiene and single-use disposal are top priorities. For a deeper look into the properties, uses, and real-world advantages of these materials, consult experts at https://viantmedical.com/capabilities/medical-grade-plastics.

A distinguishing feature of medical-grade plastics is their compliance with safety and biocompatibility standards, which are essential for ensuring patient safety and achieving optimal outcomes. Comprehensive testing is essential to mitigate risks, particularly for devices such as implants and catheters. Their versatility fosters innovation through rapid prototyping and the development of custom solutions. The role of medical plastics in infection prevention became particularly prominent during the COVID-19 pandemic, as they provided safe, disposable options while also offering economic benefits, such as lower manufacturing costs and scalability, thereby enhancing healthcare accessibility. As technology advances, tailored plastic solutions are expected to continue shaping the future of medical care.

Advancements in Biodegradable Medical Plastics

In recent years, there has been remarkable progress in biodegradable medical plastics, driven largely by a heightened global focus on sustainability and ecological responsibility. The medical sector is facing increasing scrutiny for its contribution to plastic waste, prompting the adoption of biopolymer materials, such as polylactic acid (PLA) and polycaprolactone (PCL). These biodegradable polymers are transforming applications in surgical implants, wound healing products, and drug delivery systems by providing safe degradation within the human body or the environment post-use. Their ability to break down harmlessly after performing their function helps minimize the burden on landfill sites and reduces the risk of environmental contamination. The demand for these materials aligns with sweeping regulatory and ethical commitments to reduce the ecological footprint of healthcare.

Biodegradable plastics play a crucial role in innovations such as dissolvable sutures, tissue scaffolds, and temporary support structures used during the healing process. By eliminating the need for further surgical intervention to remove implants, these materials enhance patient comfort while streamlining clinical processes. Researchers continue to modify the physical and chemical characteristics of biopolymers to optimize performance and ensure predictable, safe degradation rates. Such customization is vital in drug delivery, where controlled release and precise timing are paramount. These bioplastics also reflect a broader industry movement toward circular economy models and sustainable resource management, positioning healthcare as a driver of environmentally responsible change.

Innovations in Medical Device Manufacturing

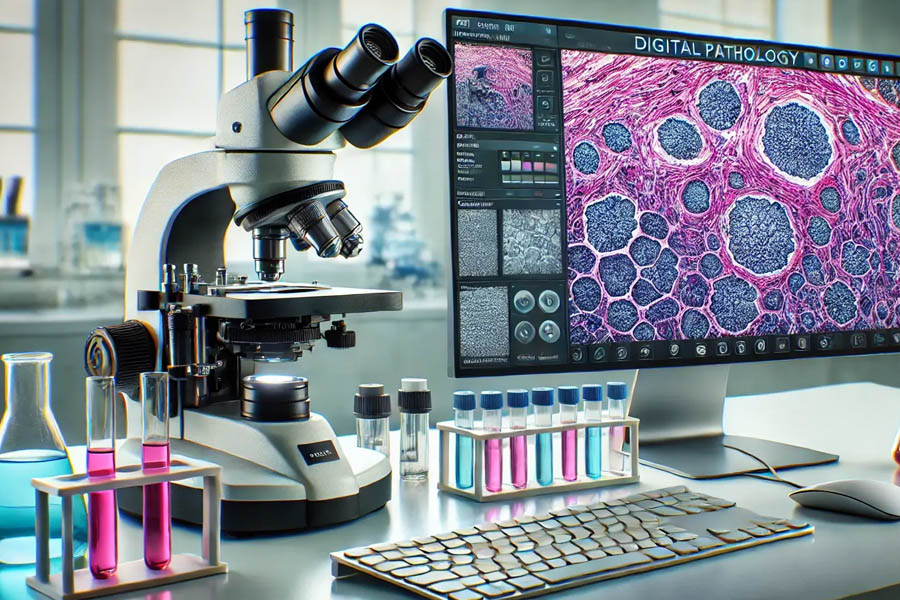

Precision engineering and cutting-edge manufacturing have driven significant advancements in the development of medical devices using plastics. Advanced CNC machining, injection molding, and additive manufacturing (such as 3D printing) allow for high-quality production of complex geometries and personalized components, ensuring both optimal function and regulatory compliance. Manufacturers are adopting high-precision techniques that maximize material performance, which is crucial for items such as prosthetics, stents, and minimally invasive surgical tools. This shift is fostering the rapid prototyping of novel treatments and patient-specific devices that push the boundaries of tailored healthcare solutions.

Additive manufacturing, in particular, is revolutionizing the way medical devices are conceived and brought to market. The process enables intricate internal structures, lightweight lattice frameworks, and custom geometry that would be impossible to achieve with traditional machining. These benefits translate to faster innovation cycles and more efficient product development. Furthermore, combining 3D printing with medical imaging data enables the precise fabrication of patient-specific anatomical models for pre-surgical planning and educational purposes, thereby driving both clinical and educational advancements.

Sustainability Challenges and Solutions

Despite the immense medical benefits, the proliferation of single-use plastic products has heightened awareness around healthcare waste and its long-term ecological impact. Hospitals generate significant quantities of disposable plastic, much of which is necessary for infection control and patient safety. Balancing the need for sterility with environmental responsibility has emerged as a major challenge. To address these concerns, leading manufacturers are exploring recyclable polymers and bio-based materials that combine functionality with environmental responsibility. Dedicated recycling programs for non-infectious medical plastics, along with initiatives supporting circular economy models, are gaining traction in major healthcare systems. Global efforts to develop sustainable healthcare plastics are expected to intensify, driven by growing environmental regulations and increasing public demand.

Some organizations are piloting closed-loop waste management systems, where select plastics are collected, cleaned, and recycled into usable goods, thereby minimizing landfill contributions. The implementation of green procurement policies, which mandate sustainable product choices, can propel further progress. As innovation in material science continues, new generations of plastics may offer even greater balance between required performance and reduced environmental impact. These collective efforts aim to ensure the quality and safety of healthcare while safeguarding the planet for future generations.

Regulatory Compliance and Safety Standards

The use of plastics in healthcare is governed by strict regulatory regimes to ensure patient safety. Global standards such as ISO 10993 and US FDA regulations require rigorous biocompatibility testing, ensuring that materials are non-toxic, hypoallergenic, and suitable for direct or indirect patient contact. Sterilization stability, chemical resistance, and the ability to withstand mechanical strain are further essential criteria. These regulatory requirements encourage ongoing innovation, stimulating the development of new formulations and manufacturing methods that address both old and emerging clinical challenges.

Ongoing evaluation and post-market surveillance are mandatory to maintain compliance and adapt to new scientific findings or emerging risks. Regulatory frameworks also require detailed traceability, robust supply chain management, and comprehensive documentation from manufacturers, supporting global collaboration and knowledge sharing within the industry. These efforts collectively foster continuous improvement and enhanced patient outcomes worldwide.

Customization and Personalization in Medical Devices

The adaptability of plastics to modern manufacturing processes—especially 3D printing and injection molding—has unlocked unprecedented opportunities for personalized healthcare solutions. Physicians and engineers collaborate to design patient-specific prostheses, surgical guides, and implants, optimizing fit, function, and aesthetic outcomes. This tailored approach supports the growing trend of precision medicine, providing patients with devices specifically designed for their individual physiology and condition. With continued advances in medical imaging and CAD software, the pace of personalization is poised to accelerate further.

Personalized implants and devices not only enhance medical outcomes but also foster patient confidence and satisfaction. These processes reduce the risk of complications and minimize surgical time by providing better anatomical fit and function. Increasingly, combination devices—medical plastics embedded with electronic sensors, smart materials, or responsive coatings—are emerging as a forefront technology. These developments will help close the gap between diagnosis, treatment, and monitoring in ever-more integrated healthcare solutions.

Future Outlook of Medical-Grade Plastics

The global market for medical-grade plastics is set for robust expansion, projected to rise from $31 billion in 2022 to $50.5 billion by 2030. This growth reflects the surging demand for innovative, eco-conscious materials and manufacturing methods that will define the next era of healthcare advancement. The integration of smart materials—such as antimicrobial plastics and advanced composites—will further strengthen infection prevention and therapeutic capabilities. Collaborative efforts between material scientists, device manufacturers, and healthcare providers will ensure that future solutions are not only higher-performing but also safer for patients and the planet.

Looking ahead, the medical plastics industry is likely to see increased R&D investment in next-generation materials—for example, plastics that deliver time-released medication or change properties in response to physiological conditions. The convergence of digital technology, automation, and materials science will underpin this innovation, driving medical devices to new levels of complexity, efficiency, and sustainability. These advancements promise improved patient outcomes, greater resource efficiency, and a smaller environmental footprint for the healthcare sector as a whole.

Conclusion

Medical-grade plastics are vital enablers of innovative healthcare, delivering unmatched versatility, performance, and safety. As sustainability and personalization become central themes, the industry’s focus on green materials and advanced manufacturing methods will help address both environmental challenges and the evolving needs of patients. The continuous evolution of medical plastics ensures their pivotal role in shaping the quality, efficiency, and future of global healthcare.