Now Reading: Why Electrical Safety Is Non-Negotiable on Every Job Site

-

01

Why Electrical Safety Is Non-Negotiable on Every Job Site

Why Electrical Safety Is Non-Negotiable on Every Job Site

The Persistent Challenge of Job Site Electrical Hazards

Electrical hazards remain one of the most persistent risks on job sites, posing threats to workers, project timelines, and efficiency. If not addressed with consistent safety measures, these dangers can quickly escalate from exposed wiring and overloaded circuits to improper grounding. The stakes are high, as even minor lapses in safety protocols can result in severe injuries, equipment damage, or costly project delays.

That’s why electrical safety is non-negotiable on every job site. Regular training, thorough inspections, and compliance with industry standards are essential to minimizing risks. Partnering with knowledgeable resources, such as divergentalliance.com, can provide valuable insights into safe practices and solutions. Ultimately, prioritizing safety protects workers and any project’s long-term success. A culture of accountability ensures that every team member takes responsibility for maintaining safe conditions. In the end, consistent vigilance keeps job sites productive and free from preventable incidents.

Common Safety Protocols for Every Crew

Implementing uniform safety protocols lies at the heart of a robust electrical safety program. Consistency and clarity are essential for reducing confusion and ensuring every team member knows what’s expected. These protocols generally encompass:

- Lockout/Tagout (LOTO) procedures:De-energizing circuits and locking out breakers before maintenance or repairs begin is critical for worker safety.

- Regular inspection and replacement:Systematic checks for damaged, aged, or malfunctioning equipment help catch issues before they escalate.

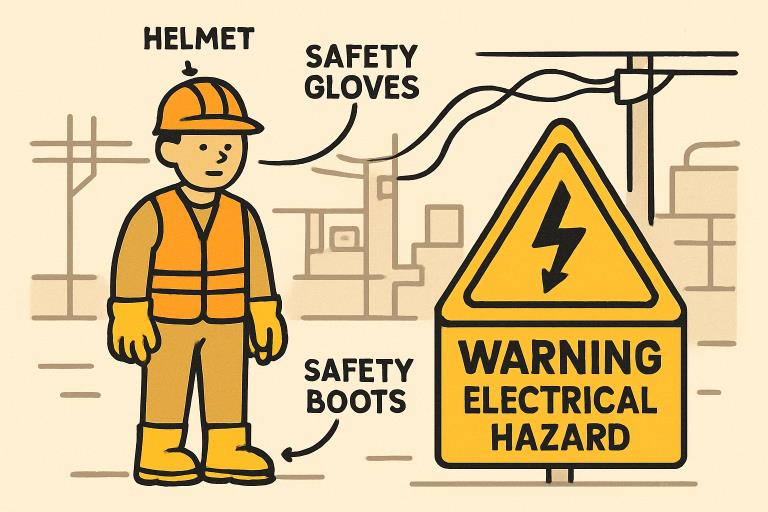

- Appropriate use of PPE:Workers should always use tested, insulated gloves, dielectric boots, and other gear suited to the electrical tasks at hand.

- Mandatory safety briefings and refresher training:Communicating hazards and procedures ahead of each project reinforces workplace vigilance and accountability.

Firms that strictly adhere to these protocols often see incident rates plummet, along with enhanced crew confidence and morale.

Why Ongoing Training Matters

Even with the most stringent rules, the value of hands-on, ongoing education cannot be overstated. Regular training and certification keep teams sharp and responsive to evolving hazards and codes. Retaining each year reduces workplace electrical injuries and helps organizations avoid costly shutdowns and legal liabilities.

This commitment to perpetual learning ensures that all workers—rookies and veterans alike—can spot new threats and apply updated best practices. It also sends a message: safety is ongoing, and there is never a box to check and forget.

New Trends in Electrical Safety Gear

Technological progress enhances safety for electricians and technicians with advanced PPE like flame-resistant, breathable clothing, lightweight insulated tools, and arc flash sensors that provide immediate warnings. Cloud tracking of safety gear and wearable health monitors is now used on high-risk sites to alert supervisors to real-time threats and vulnerabilities. These innovations go beyond compliance, creating safer and more responsive workplaces.

The Role of Leadership in Promoting Safety

Leadership is vital for embedding electrical safety deep within the organizational culture. Foremen, supervisors, and company owners must lead by example by following protocols, halting unsafe operations, and promoting transparent, non-punitive hazard reporting. When management participates directly in safety training, incident analyses, and corrective action planning, employees are far more likely to adopt similar attitudes and habits.

Building a Proactive Safety Mindset

The shift from a reactive stance—where accidents drive change—to a proactive safety culture is transformative. This involves conducting risk assessments before each new task, keeping thorough records of near misses and lessons learned, and incentivizing smart, safe decision-making. Open communication fosters peer accountability and ensures that new hazards are swiftly identified and mitigated.

Companies that make electrical safety foundational—rather than an afterthought—achieve compliance, operational excellence, and genuine peace of mind.

Looking Toward the Future

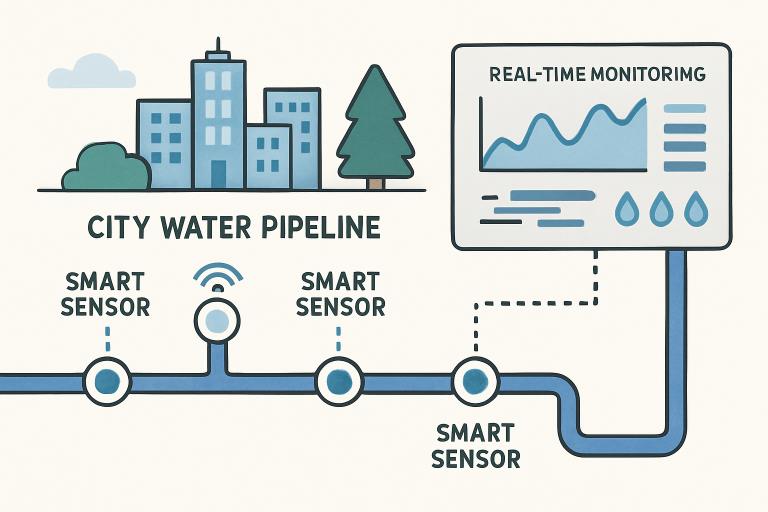

Emerging technologies are poised to revolutionize how job sites identify and neutralize hazards. Digital hazard mapping tools and AI-enhanced monitoring platforms can now predict dangerous scenarios before they unfold. For organizations that prioritize early adoption of these tools, the outcome is a competitive edge: fewer workplace interruptions, healthier employees, and tangible cost savings. To stay ahead, it’s crucial to keep pace with future trends in electrical safety and adapt internal policies accordingly.

Final Thoughts

Electrical safety is a universal concern that demands every project stakeholder’s vigilance, knowledge, and teamwork. Organizations can dramatically reduce accident rates and save lives by investing in continuous learning, best-in-class equipment, and a culture that empowers everyone to speak up about risks. As new challenges and technologies emerge, embracing a forward-thinking approach ensures that every worker returns home safe—proving once and for all that safety on the job site is never negotiable.